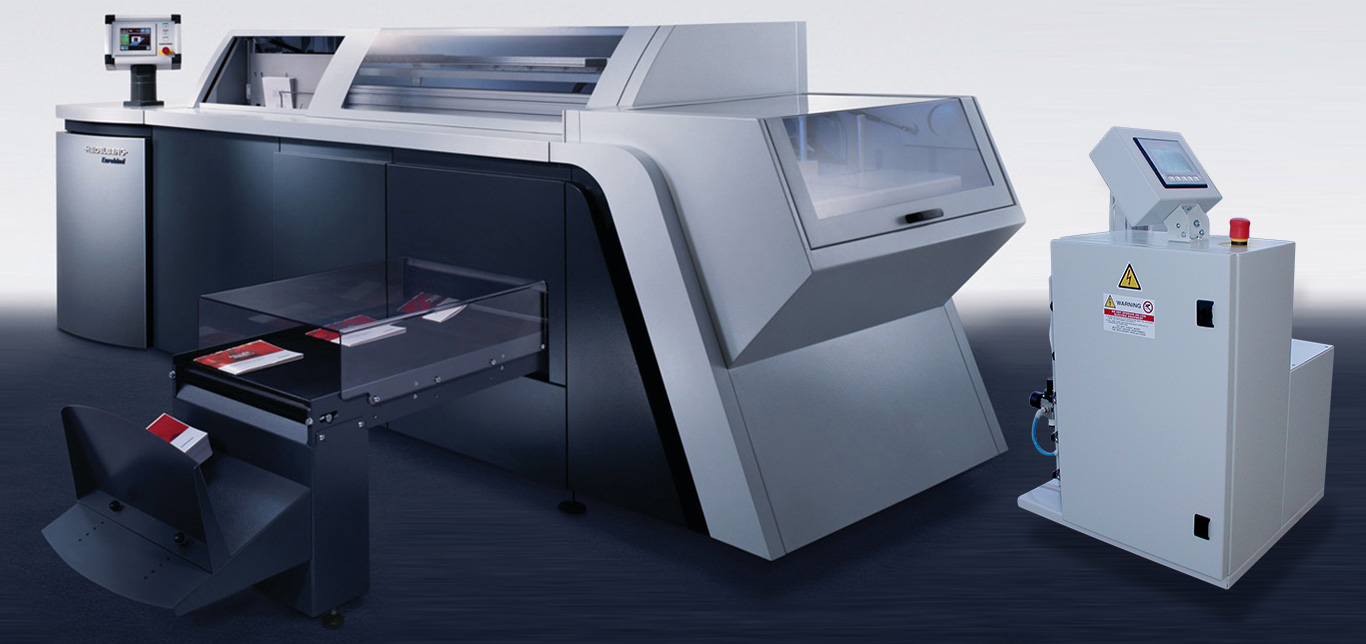

Project Description

YOUR PERFECT BINDER CAN BE EQUIPPED BY

THE HOTMELT / PUR CONVERSION KIT

10 Good reasons to choose

the Conversion Kit for HotMelt / PUR Perfect Binders!

1 SIMULTANEOUS USE OF HOTMELT AND PUR TECHNOLOGY

2 TIME REDUCTION, COMPARED TO A TRADITIONAL PUR SYSTEM

3 HIGHER GLUING STRENGTH ON SPECIAL PAPER TYPES

4 RE-USE AND REVALUATION OF OLD PERFECT BINDERS

5 EASY INSTALLATION

6 SPARE PARTS - ALWAYS AVAILABLE

7 SAFETY STANDARD ACCORDING TO REGULATIONS

8 PATENTED TECHNOLOGY

9 USER FRIENDLINESS

10 ELIMINATION OF SEWING BINDING

GEAR PUMP DRIVEN PUR GLUING SYSTEM

Eurotecnica Service is the first and officially recognized company to make the conversion Kit HOTMELT-PUR for almost all the Perfect Binders today in the market!

With the strength from the experience gained with the cooperation with HEIDELBERG group, we have developed a unique gluing system with polyurethane glue for binding the book blocks by means of a combined gluing system with two different glue types normally used in top class binders.

Spine gluing with PUR glue (polyurethane reactive)

Side gluing with Hotmelt glue.

The application head and the glue pot for side glue are placed in the space left free by the existing hotmelt pot, it means no modification for the frame of the machine!

There is neither need of dry air, nor of compressors for waterless air, because the system is designed to avoid any contact with the air which could cause reticulation of the glue.

The system is ideal for small and medium-size printing runs and guarantees a high quality of the product in shorter time with low prodution costs!

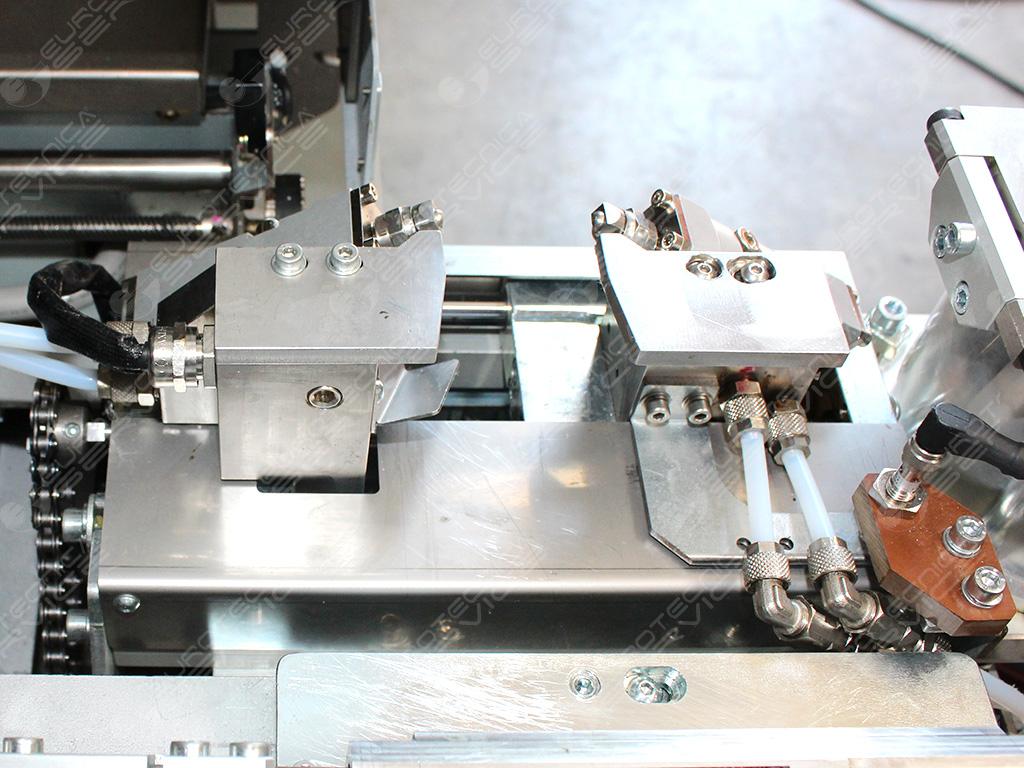

The system is composed by a PUR gluing head only for gluing the book spine. The PUR gluing head is fed by a variable/changeble speed gear pump driven premelter placed in the down side of the machine. The premelter is equipped with a tank for 2 kg PUR glue cartridge (that has to be put in with its own wrapping to avoid contact with the outer air) connected to the application head by a heated tube.

It’s important to underline that our system heats only the quantity of glue needed during the job, unlike other systems heat the whole quantity of glue every time the machine is switched on, even for low production the whole cartridge is melted, which leads to deterioration of the quality relevant properties of the glue at the expense of the finished product. Our system avoids waste and the quality of the glue is always preserved.

The system allows to adjust the pressure and the flow rate of the pump to guarantee an uniform and homogeneous glue spreading on the whole book spine, completely automatically only by entering the book thickness as input data.

Additionally, an innovative and completely automatic system for cleaning at the end of each working cycle is implemented in order to clean the application head easily and quickly, making the maintenance of the application head much more easy than in other systems.

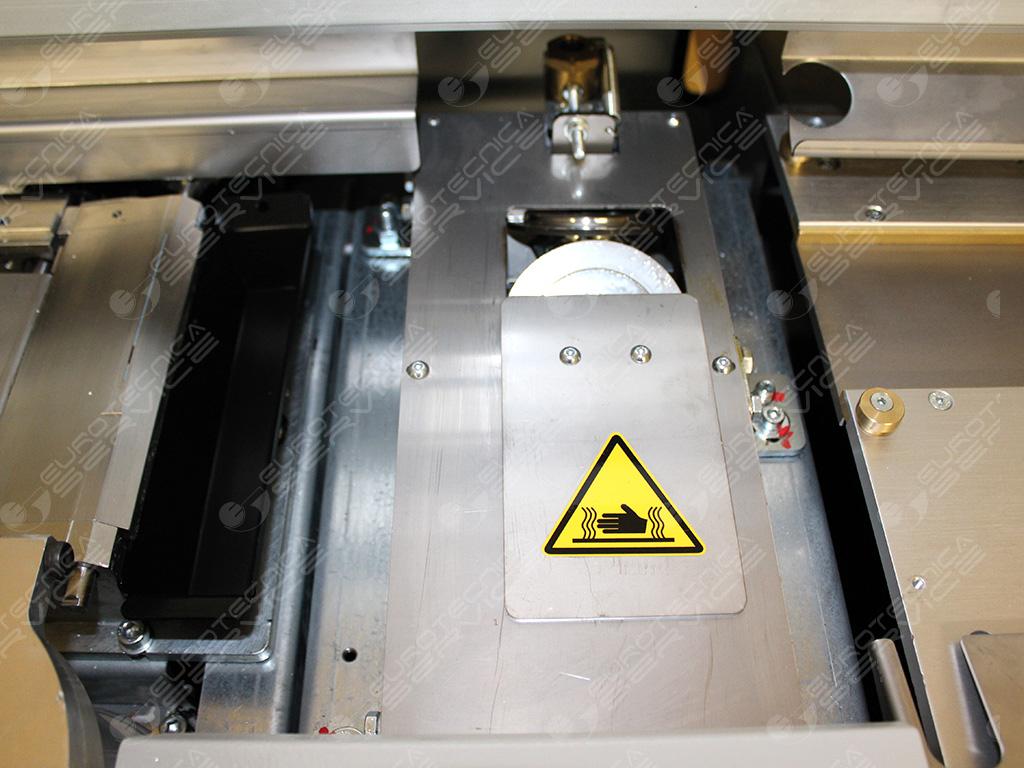

The side glue is applied at the sides of the book blocks by means of two disks immersed in the Hotmelt glue, contained in a pot separated from the PUR application head.

These aims have been made to guarantee a higher stability of the book block during the process and to reduce the waiting time before trimming.

Book thickness adjustment (max 50 mm-1,97 in) can be either manual or automatic on both PUR glue head and Hot-melt glue applicators, using a knob or touch screen display.

INSTALLATION:

For the machine installation with the new gluing system, only a new power supply is required for the new 400V 3F + N + Pe fuser power 2Kw power. The other functions will be as originally.

Encumbrances:

OPTIONALS:

kit consisting of::

- Special tool for rough treatment of the spine of the book

Consumables:

- Cartridge glue Kg.2 PU90

ADVANTAGES:

Ensure, uniform and costant coverage of glue on the spine of the book. Only heat up the required quantity of glue, to avoid waste and deterioration. Insert the glue cartridge directly without removing or cutting the hermetic pack. To be independent of PUR glue head

Head PUR gluing

Hot Melt side glue

Nozzles

Fuser

External fuser on brackets