Project Description

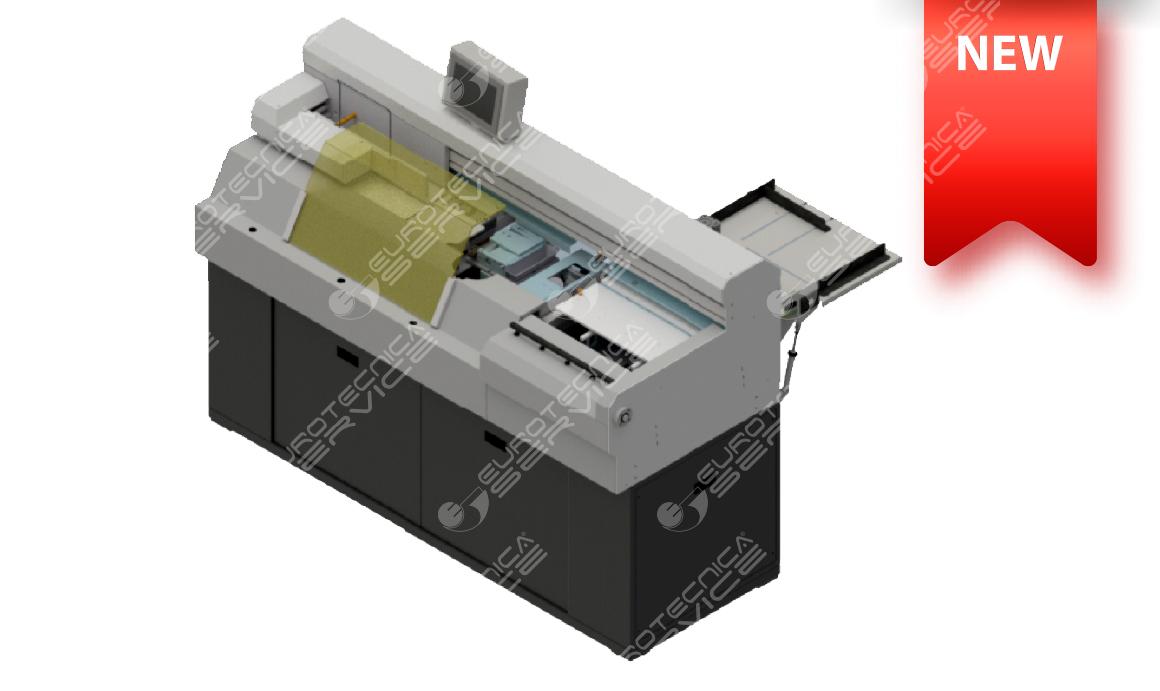

EUROBIND EB300P-CF THE FIRST PERFECT BINDER IN ITS

CATEGORY WITH AUTOMATIC COVER FEEDER

AND CREASING

EUROBIND EB300P-CF is a professional single-clamp perfect binder with double gluing system.

It is an extremely compact binder enclosing a one-of-a-kind PUR-glue extrusion system with no need for dry air and compressors for anhydrous air avoiding any contact with the ambient air which could lead to reticulation of the glue.

This perfect binder is ideal for short and medium print runs, guarantees high quality product with short time to trim and low production costs.

L’ EUROBIND EB300P-CF is the first machine equipped with an automatic cover feeder inserter with suction cups with top loading and creaser, the most suitable for digital jobs.

Possibility of adjusting the engraving pressure.

Number of measures 6 or more, all programmable and excludable from the control touch panel.

Possibility of working with only the cover feeder for automatic loading even without a creaser.

A work cycle is also foreseen with manual loading of the covers in order to be able to carry out non-format jobs excluding both the cover feeder and the creaser.

L’ EUROBIND EB300P-CF is the first binder with these characteristics to use a combined system for binding the book block with 2 different types of glue usually used with higher-end binders.

Spine with PUR glue (Polyurethane Reactive)

Sides with Hotmelt glue (EVA)

- The spine gluing system consists of an application head fed with PUR glue by a premelter with variable speed and variable pressure gear pump.

- The premelter is equipped with a tank where a 2-kg PUR glue cartridge -intact in its package- is to be inserted, no need to remove or cut the wrapping. A heated tube connects the premelter to the application head.

- A key feature of our system is the fact that only the needed quantity of glue is molten during the binding process, unlike other systems where the whole PUR glue in the tank is molten every time the perfect binder is switched on.

- The system, completely integrated in the perfect binder, allows to adjust pressure and flow rate of the pump in order to guarantee a homogeneous and constant spreading above the whole spine of the book block automatically

- Touch-screen color operator panel. Italian language or at the request of the customer quick learning with simple symbols and step-by-step guide to the commands for using the machine

- Side glue is applied at the sides of the book block by means of two disks immersed in Hotmelt glue in a tank treats with non-stick, separated from the application head for PUR glue. This is to guarantee a higher stiffness of the book block, so to allow further handling/processing of it within much shorter time respect to books totally bound with PUR glue.

- A fast, innovative and automatic cleaning system of the application head -of our own design- is available at the end of each working cycle. The cleaning system is user-friendly, fast and requires only a reduced consumption of cleaner. At a new switch on this guarantees a quick resumption of the work without clogging problems at the glue outlet channels and makes the work of the operator easier and more straightforward than other systems.

Questo garantisce alla riaccensione una rapida ripresa del lavoro senza problemi di intasamenti dei canali di fuoriuscita della colla e rendere più semplice e pratico il lavoro dell’operatore rispetto ad altri sistemi.

Cordonatore a battuta con possibilità di regolazione della pressione di incisione. Numero di battute previste 6, tutte programmabili ed escutibili.

Dati tecnici

| Production | |

|---|---|

| Mechanical cycles/h | Approximately 300 |

| Book shelf | |

|---|---|

| Height adjustable 0 – 2mm | Yes |

| Clamp | ||

|---|---|---|

| Number of clamps | 1 |  |

| Opening and closing of the clamp | Pneumatic | |

| Electric adjustment to book block thickness | Yes, electrically automatic | |

| Automatic return motion | with push button control | |

| Variable travel speed | Yes |

| Milling device | ||

|---|---|---|

| Cutting depth of 0-2 mm | adjustable |  |

| notcher slitting knife 3 | Possibility to add 3 more tips (optionals) | |

| excludable electrically | Yes from Touch Panel (mechanical exclusion of optionals). | |

| Aspirator chips connected to the machine to function in contemporary |

| Application head with variable light | ||

|---|---|---|

| Book thickness guide adjustment automatic electric |  | |

| Max thickness 50 mm | ||

| PUR glue melter | ||

|---|---|---|

| Pressing plate type with volumetric gear metering pump with adjustable speed and pressure. Tank capacity Kg. 2 |  | |

| Hot Melt side glue tank | ||

|---|---|---|

| glue tank with non-stick treatment | Automatic electric |  |

| Automatic electric glue disc opening/closing adjustment | Yes | |

| Max opening 50mm | 50 mm | |

| Excludable | Yes |

| Nipping device | ||

|---|---|---|

| Pneumatically | Yes |  |

| Pressure on the book adjustable | Yes | |

| Automatic Thickness Adjustment book | Yes | |

| Presence control cover | Yes | |

| Pressing time adjustable | Yes by Touchscreen | |

| Plates treated in non-stick material | ||

| Excludable | Yes |

| Control panel | |

|---|---|

| Colour Touchscreen Language: Italian or other upon customer demand User-friendly, quick and easy to learn, uncomplicated symbology and stepwise guide to commands for machine use. Many other functions are available such as Preheating of the machine for reducing the waiting time during glue heating, counter of produced copies, signalisation of errors, signalisation of alarms, miscellaneous information etc. Glue application length adjustable from Touchscreen |  |

| Type of gluing | |

|---|---|

| Spine with PUR glue (Polyurethane Reactive), | in PUR with sealing head with hermetic circuit without emissions of fumes glue with device start – integrated glue stop |

| Side with Hotmelt glue (EVA) | Hotmelt with spreading discs immersed in a separate tank |

| Loading covers | |

|---|---|

| Cover loading with top grip with suction cup suction system. The creasing can be excluded Number of creases 6 including courtesy Adjustable stop pressure Cover pile height approx. 5 cm Possibility of using only the feeder |  |

| Book format | ||

|---|---|---|

| Width h : | max. 300mm |  |

| Width h : | min. 90mm Possibility of higher width with manual loadingale | |

| Height b : | max. standard 440 | |

| Height b : | min. 50mm | |

| Thickness | max. 50mm | |

| Thickness d | min. 1mm |

| Cover dimensions | ||

|---|---|---|

| Width Z : | max. standard 650 (with automatic load function) Possibility of higher width with manual loading |  |

| Width Z : | min. 140mm | |

| Height W : | max.440mm | |

| Height W : | min. 50mm |

| Integrated electric cabinet | |

|---|---|

| Power supply: : | 400V ± 5%, 50Hz, 3PH+N + PE / 13A 6,5 KW |

| Power socket | with 20Agg fuse protection or alternatively 20A automatic switch charged to the customer. |

| Compressed air: | Max. static working Pressure: 7 bar |

| Diameter of the compressed air inlet fitting: | Ø 8 mm |

| Consumption max. of compressed air: | 10 Nl/min |

| The compressed air supplied to the binder must be as dry as possible and free of oil and impurities | |

| Dimensions and weight of the binder | ||

|---|---|---|

| – Lenght : | 1700 mm |  |

| – Width : | 1200 mm | |

| – Height : | 1400 mm | |

| – Weight : | approx. 300Kg |